Growth, development and achievements in the last 20 years

Accumulation of inventions, advances and applied solutions to small Blimps and Airships

Short history

We started modestly in 1999, where our goal was to adopt the technology for the production of advertising Blimps. But we quickly realized that such stable and vibration-free flying platforms could be used for other purposes as well. Since 2003, we have been working on the development of Blimp Aero Photo systems as well as free-flying Blimps. To date, we have managed to develop 8 standard sizes of RC Blimps (from 2 to 12 m) as well as a number of custom sizes that we have exported around the world (mostly USA and Germany). The RC Blimps offered on this site are the result of countless hours of design, work and testing.

As a result of persistence and dedication we have had the honor to work and collaborate for the following clients: Airbus, MIT, Cornell, Murdoch, National Geographic, Aerospace (USA, Europe and Italy), Skylifter, GreenPeace, Ocean Cleanup, Opera House Zurich, Red Cross Museum, WSAR, Bristol, NATO Davos, SAS, Samsung, Spar, Desjardins, Nivea, Puma, Accenture, JM industries, and many more Universities, Institutes, Companies and private clients.

The latest focus of our work in developing LTA technology is work on the Blimp drone prototype

It is an indisputable physical fact that 1 m3 of helium or hydrogen can "lift" 1 kg of cargo (more or less depending on the purity). And the "trick" in the development of LTA technology is how to make the best use of that fact. The background is certainly the reduction of the weight of the necessary materials and components for the actual construction of the Blimp, which would make the best use of it. However, it is a "necessary" background. The key is in the design itself - how best to combine all the components that make up the blimp and remove everything unnecessary. The excess of components directly affects the weight, which produces a larger volume of the blimp - thus, a greater aerodynamic resistance of the envelope. Which is certainly undesirable.

Based on our 30 years of experience in LTA technology, we are currently preparing a Blimp drone prototype. The power of the Blimp is significantly increased with 4 motors on the side (in the horizontal axis) and the control itself is improved with the use of Arduino motor control. The development of drones has greatly helped the development of blimps with the appearance of a series of innovations and significantly lighter electronics, which at the same time are extremely capable in terms of function.

More ...

Achievements and Advances in LTA Technology by Aero Drum Ltd

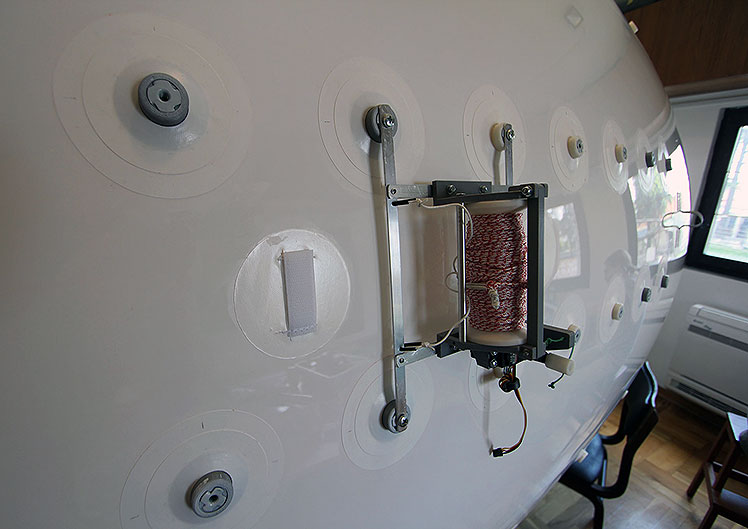

SAFETY VALVE AND SAFETY REEL: One of the first innovations we had to adopt was the safety valve. As it is obligatory by law as well as necessary, it is logical that we started from it first. Today we have two types of safety valves: one that just opens and the other that can both open and close. We install them in external RC Blimps and other custom shapes. The same was true for the safety reel which has 100 m 2 mm dacron rope.

ENVELOPES OF THE BEST POSSIBLE QUALITY: Of course, the envelopes must be safe, somewhat elastic, B1 fire retardant and minimally leaky. Here we tried a number of techniques and the best proved to be a manual technique with a tape that secures the welds. We compared it to the welds of ultrasonic machines and our welds proved to be much better.

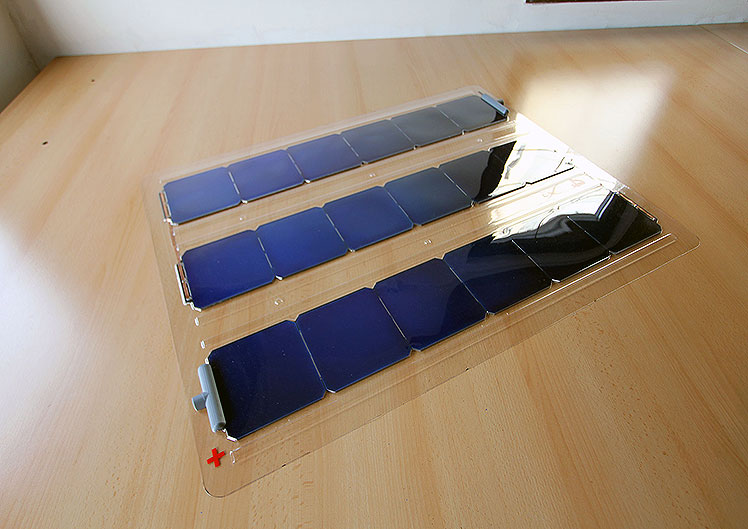

FLEXIBLE SOLAR MODULES: Since Blimps can float almost indefinitely (which is their positive nature), in order to make the best use of the energy that drives them, it must also be long-lasting. During 2020-2021, we developed elastic solar modules of 24% efficient Maxeon solar cells.

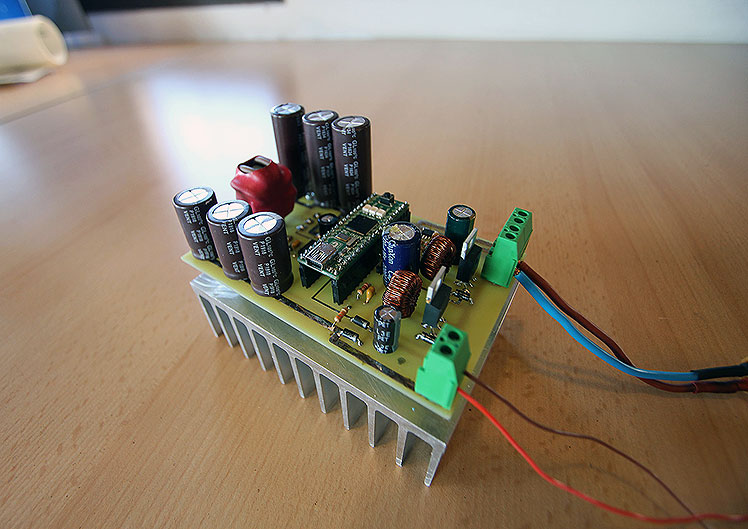

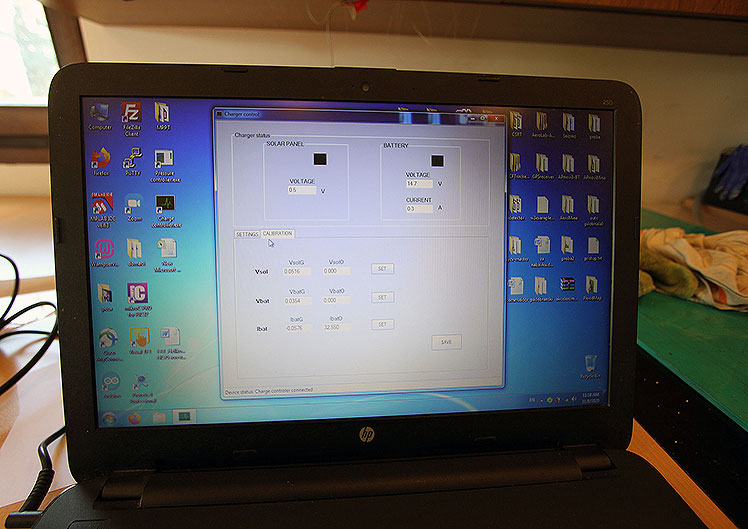

INTELLIGENT POWER DISTRIBUTOR: In order to be able to use the energy obtained from solar modules on Blimp, we have also developed a device that distributes energy. It directs the energy from the solar cells partly to charging the batteries and the other part to the systems on Blimp (motor, receiver, servo, ...).

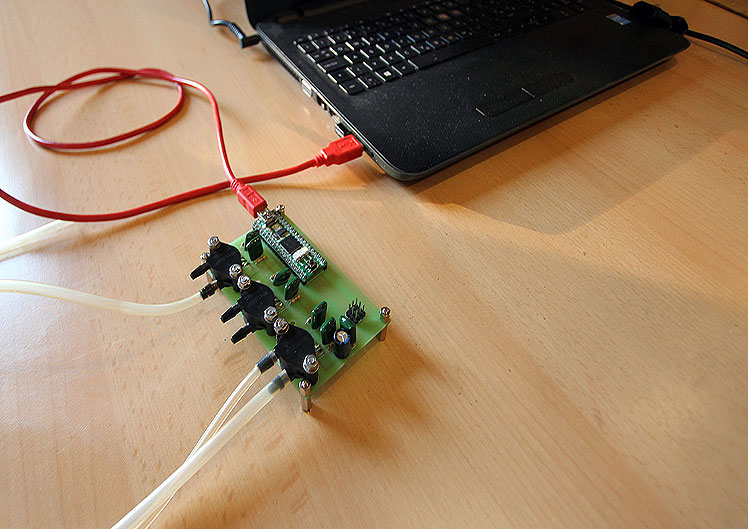

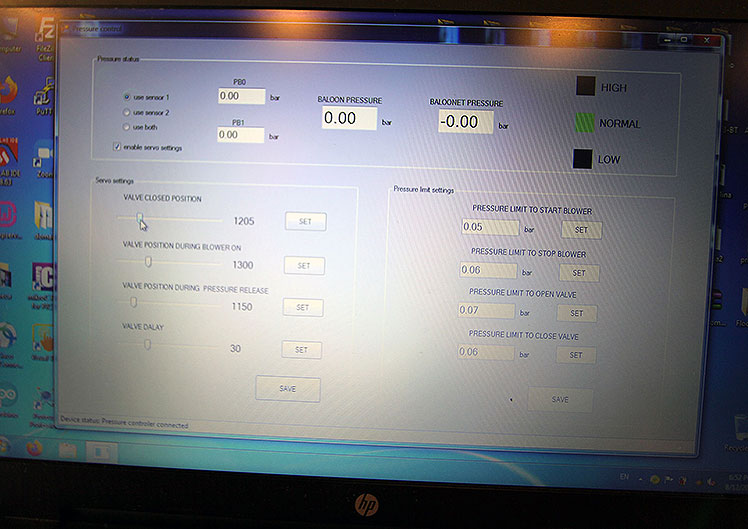

BALLONET HARDWARE AND SOFTWARE: If long autonomy (days) is expected from the Blimp besides solar modules ballonet is also crucial. A ballonet is an inner balloon that regulates the pressure of the envelope (outer shell) by inflating and deflating. The ballonet also affects the buoyancy of the Blimp. In order for all the elements on the Blimp to be tightly attached and have function, the pressure in the envelope must be within certain limits. We developed hardware and software that automatically maintain pressure in the Ballonet.